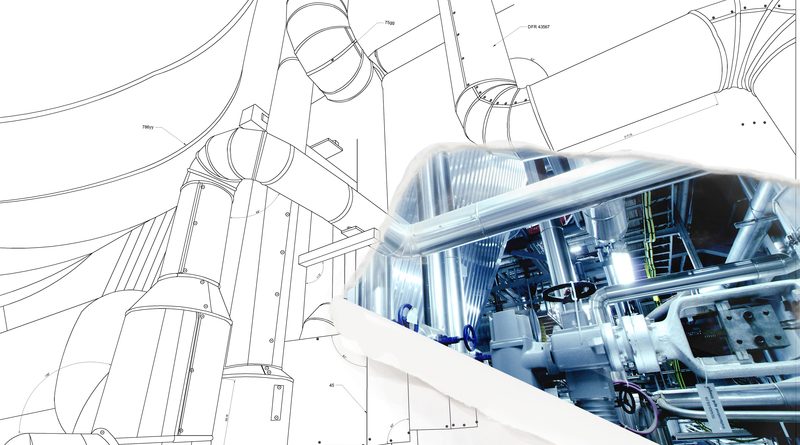

CAD: What It Is, And How It’s Changing Industries

Computer-Aided Design or CAD is a method of designing, analyzing, and modifying designs using computer software and is the main tool in an engineer’s toolbox. CAD has been around since the 1950’s and has grown exponentially along with the advent of computer-aided manufacturing software. Computer-Aided Manufacturing or CAM allows the design to become a reality using tools like a CNC, water-jet cutter, or 3D printer. Below are some industries making huge strides in efficiency thanks to CAD and CAM.

Dental Industry

In recent years, CAD has made its way into your dentist’s office by offering 3D scanning technology. According to Dental Care Providers of America, “Using special software, the data from scans of a tooth are used to generate a design (CAD) for a custom crown. This program will also generate a custom blueprint and guidelines to manufacture the new crown (CAM) with a milling machine.” This involves making a precise “map” of a patients mouth, showing all the curves, bumps and crevices that make up your teeth, gums, and jawline. Bringing this map into CAM allows the user to create custom solutions that fit and contour to their mouth perfectly. This not only improves the experience for the customer but also improves the quality of the product and decreases the time it takes to manufacture.

Architectural

For an architect making very large-scale designs, CAD is critical in the design before the first brick is ever laid. Methods such as FEA, or finite element analysis, allow engineers to analyze the strength of structures under load, calculate wind loading, and look at the design in real time to predict failure. Designing complex architectural concepts and making things spring to life with 3D imaging helps the architect communicate to the customer what their design will look like. The Digital School explains that “Modern CAD software offers several advantages, including the ability to simulate the movement of a constructed machine and the ability to simulate a variety of environments and stresses on a prototype to estimate a product’s lifespan.” Drafting plans in CAD has never been quicker which translates to more money in the architect’s pocket and a quicker turnaround for the customer.

Manufacturing

Even though many businesses have outsourced their manufacturing overseas, there are many who haven’t–and they’re experiencing a CAD-driven revolution. It’s one thing to have a production queue; it’s quite another to have it directly hooked up to your design process. Being able to sculpt a product in a CAD system is wonderful enough; then you can feed it through your in-house machinery immediately. Fluent Conveyors suggests that in-house production equipment is perfect for pairing with CAD; it fits together like a hand in a glove. This immediate manufacturing process is thrilling and it’s really stirring things up on the production side of things. Now prototypes accelerate towards greenlighting for manufacturers, there’s less cost to invest in new enterprises, and experimentation is much more viable. All of this is possible because of powerful new CAD integrations that make in-house manufacturing more and more viable as time goes on.

Automotive

Engineers are consistently testing new streamlined car shapes, features, and ideas to make their designs as efficient and technologically savvy as possible. Calculating wind resistances, engine combustion efficiencies, and even mapping the electrical system in each car is needed to optimize the end design. None of this would be possible without the help from CAD and CAM. The automotive industries efficiency is based almost entirely on their CAM process and methods. The sheer volume of vehicles being made would not be possible without the help of CAM, and the quality and consistency of the end product have everything to do with this process.

Nearly every industry uses CAD and CAM software to some extent. Engineers and experts use these tools to make quick work, quick changes, prototypes and cut costs. They provide effective finite element analysis when needed and are also providing small business with quick prototyping abilities crucial to getting their business off the ground.

Want to read about other integral business software and technology? Check out our Technology Column to stay up to date on the latest news!